Call it a “Forrest Gump moment;” an instance of being in the right place at the right time for no other reason than just plain luck. A “Forrest Gump moment” is based upon Tom Hanks’ character in the movie “Forrest Gump,” a guy who always seemed to be in the right place at the right time meeting Presidents Kennedy, Johnson and Nixon at critical points in American history.

I too have had a Forrest Gump moment in meeting President Reagan, however, my deeper Forrest Gump moments have been my long association with the history of analytics. I was fortunate to be at the birth of the Business Intelligence and Data Warehouse era while working for Metaphor Computers to deploy Decision Support Systems across Procter & Gamble in the late 1980’s. And was fortunate again in the late 2000’s to be at the launch of the Data Science era while building Advertiser Analytics at Yahoo.

Now again I find myself at another Forrest Gump moment in my opportunity Hitachi Vantara. We are at the cusp of the next Industrial Revolution fueled by new technologies such as autonomous vehicles, VR/AR, AI, robotics, blockchain, 3D printing and IoT. The purpose of this blog is to provide some insights into how to properly prepare to derive and drive new sources of customer, product and operational value for this next Industrial Revolution – Industry 4.0.

Birth of Industry 4.0

A recent Deloitte report titled “Forces of Change: Industry 4.0” describes Industry 4.0 as such:

“Industry 4.0 signifies the promise of a new Industrial Revolution—one that marries advanced production and operations techniques with smart digital technologies to create a digital enterprise that would not only be interconnected and autonomous but could communicate, analyze, and use data to drive further intelligent action back in the physical world.”

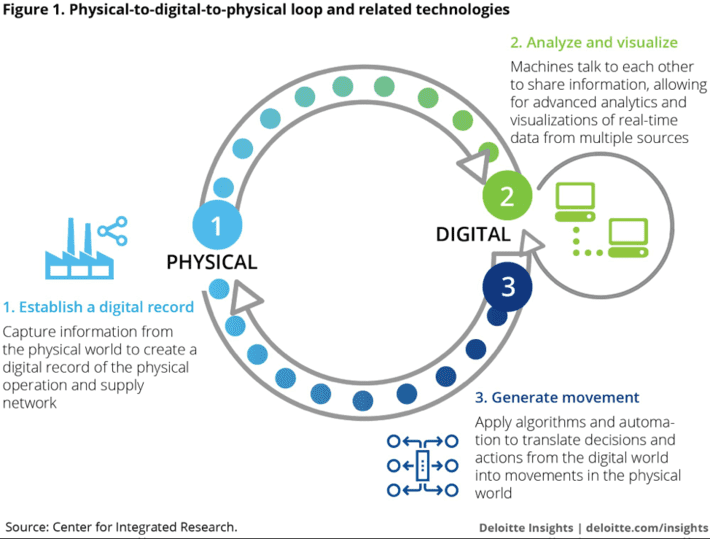

The key aspect of Industry 4.0 is the melding of the physical and digital worlds around new sources of operational data that can be mined to uncover and monetize customer, product, service and operational insights (see Figure 1).

Figure 1: Deloitte “Forces of Change: Industry 4.0”

Analytic Profiles for the human players and Digital Twins (see Figure 2) for the physical devices, will play a critical role in powering this “Physical to Digital to Physical” (PDP) loop:

- Physical to Digital: Capture information from the physical world and create a digital record from physical data.

- Digital to Digital: Share information and uncover meaningful insights using advanced analytics, scenario analysis, and artificial intelligence.

- Digital to Physical: Apply algorithms to translate digital-world decisions to effective data, to spur action and change in the physical world.

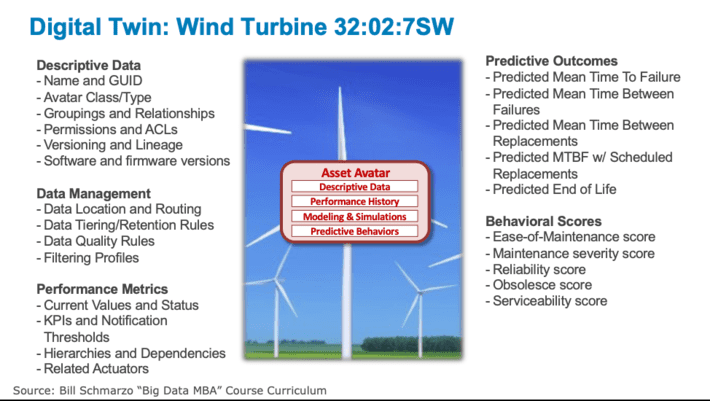

Figure 2: Digital Twin Example

A Digital Twin is a digital representation of an industrial asset that enables companies to better understand and predict the performance of their machines, find new revenue streams, and change the way their business operates.

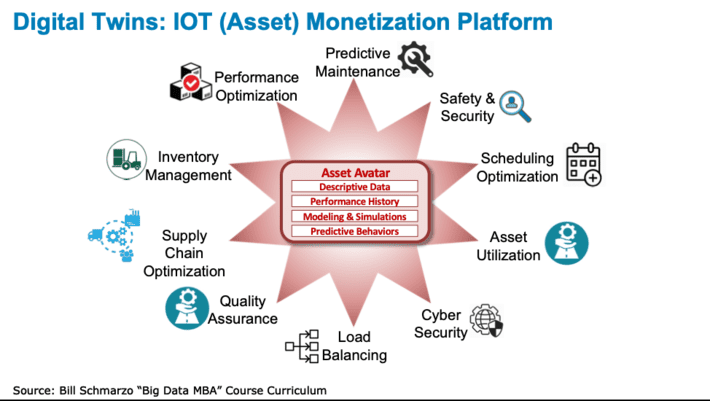

In the world of Industry 4.0, the Digital Twin is the foundation for IoT monetization. It is around these Digital Twins that organizations will build intelligent IoT applications such as predictive maintenance, inventory optimization, quality assurance and supply chain optimization (see Figure 3).

Figure 3: Monetizing Digital Twins Across Industrial Use Cases

See blog “Leveraging Agent-based Models (ABM) and Digital Twins to Prevent In…” for more details on Digital Twins.

Understanding Industry 4.0 Challenges

The biggest challenges for Industry 4.0 will be where and how to apply these new industrial technologies to derive and drive new sources of customer, product, operational and market value. However, we are fortunate to have learnings from previous revolutions – Industrial and Information – that we can apply to Industry 4.0.

In the blog “How History Can Prepare Us for Upcoming AI Revolution”, we discuss how thoserevolutions were fueled by organizations that exploited new technology innovations to identify and capture new sources of customer, operational and market value creation. The industrial Revolution was driven by new technologies such as interchangeable parts (the famous ¼” bolt), specialization of labor, factory floor assembly concepts, and availability of steam power. The Information Revolution was powered by new technologies such as x86 and MS-DOS/Windows standardization, packaged database and transactional applications, and availability of the internet.

And the driving force for capturing the economic benefits from each of these revolutions, and what are seeing today with the Intelligence Revolution, was the transition from hand-crafted solutions to pre-packaged, mass manufactured solutions. I expect the same pattern from Industry 4.0.

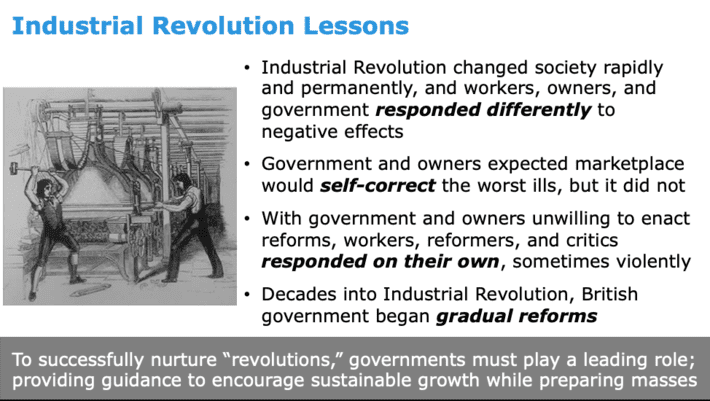

One other Industry 4.0 challenge with which organizations must wrestle is the role of the government (in the form of regulations that nurture both competition and collaboration) and universities (in preparing the workers for Industry 4.0) in working with industrial concerns to accelerate the preparation and ultimate adoption of Industry 4.0 (see Figure 4).

Figure 4: Source: “How State Governments Can Protect and Win with Big Data, AI and Pri…”

There must be strong collaboration, like what I am seeing from organizations like Team NEO(Northeast Ohio) and Jobs Ohiothat are driving collaboration between government, universities and industrials like Hitachi.

Industry 4.0 – Creating Smart Products and Spaces

“Tomorrow’s market winners will win with the smartest products. It’s not enough to just build insanely great products; winners must have the smartestproducts!”– Bill Schmarzo

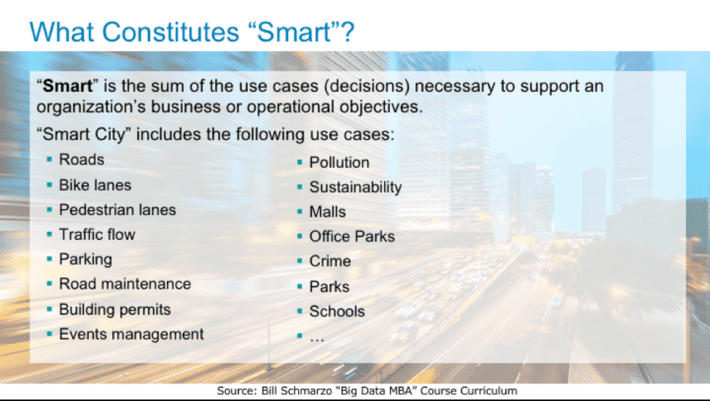

Smart is one of those over-used, poorly-defined terms that float around IoT and Artificial Intelligence (AI) conversations. So what do we actually mean by smart? For purposes of my teaching, I define “smart” as:

“Smart” is the sum of the decisions (optimized) in support of an entity’s business or operational objectives.

Organizations need to make the necessary investment (in techniques like stakeholder personas, stakeholder mapping, customer journey maps, prioritization matrix) in order to identify, validate, value and prioritize the decisions or use cases that comprise a “smart” entity. For example, Figure 5 outlines some of the decisions or use cases that a city would need to optimize with respect to a “smart city” initiative.

Figure 5: Example of the Decisions or Use Cases that Comprise a “Smart” City Initiative

See the blog “Internet of Things: Getting from Connected to Smart” for more details on creating “Smart” entities.

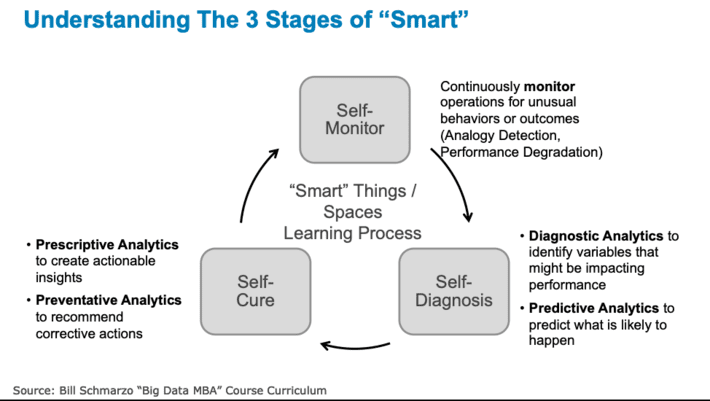

Once we have identified, validated, valued and prioritized the decisions or use cases needed to optimize our “smart” products and/or spaces initiative, we now need to develop the data management and analytics strategy to “operationalize smart”; that is, we want to create “smart” products and/or spaces that can self-monitor, self-diagnose and self-heal (see Figure 6).

Figure 6: Understanding the 3 Stages of “Smart”

The 3 stages of a continuously-learning “Smart” entity that we discussed in the blog “3 Stages of Creating Smart” are:

- Self-monitoring: An environment that continuously monitors operations for any unusual behaviors or outcomes (Analogy Detection, Performance Degradation).

- Self-diagnosis: Leverages Diagnostic Analytics to identify the variables and metrics that might be impacting performance, and Predictive Analytics to predict what is likely to happen and when it is likely to happen.

- Self-heal: Applies Prescriptive Analytics to create actionable insights, and Preventative Analytics to recommend user or operator corrective actions to prevent problems such as unplanned operational downtime.

Preparing for Industry 4.0

There is much hard work that organizations need to do to prepare for Industry 4.0 including:

1) Begin with an End in Mind.Understand your organization’s key Business Initiatives. Understand what’s important to the organization from a business, financial and/or customer perspective, and use that to frame and accelerate the monetization of these 4IR technologies. While we may not understand the technology journey that we’ll experience trying to reach that end, the end point should not be a mystery.

2) Understand the Key Industry 4.0 Technology Capabilities…But Within a Business Frame. It’s important for IT to gain familiarization with how the 4IR technologies work, what’s required to support the technologies, and what sorts of business and/or operational opportunities can potentially be addressed with these 4IR technologies.

3) Build out the Solution Architecture. Organizations should embrace a holistic architecture that supports these 4IR technologies in order to deliver “intelligent” Industrial applications (applications that get smarter with every customer interaction) and “smart” entities (that leverage edge-to-core IOT analytics to create “continuously learning” entities).

4) Use Design Thinking to Drive AI Organizational Alignment and Adoption. Embrace Design Thinking as a way to drive organizational alignment and adoption with respect to where and how these 4IR technologies can be best deployed to drive meaningful business and operational value.

5) Build out Organization’s Data and Analytics Capabilities.Become expert at acquiring, integrating, cleansing, enriching, protecting and analyzing/mining the data that is the source of customer, product and operational insights that power the organization’s top priority business initiatives.

6) Operationalize the Analytic Insights. Embed analytic insights and evidence-based recommendations into smart products and spaces that learn from each customer and/or operational interaction.

7) Monetize the IoT Edge. Leverage IoT edge to enable near-real time operational and product performance optimization that further enhances business decision-making and extends more value to customers and operations.

I think even Forrest Gump would agree that it’s a good time to be in the data and analytics business.