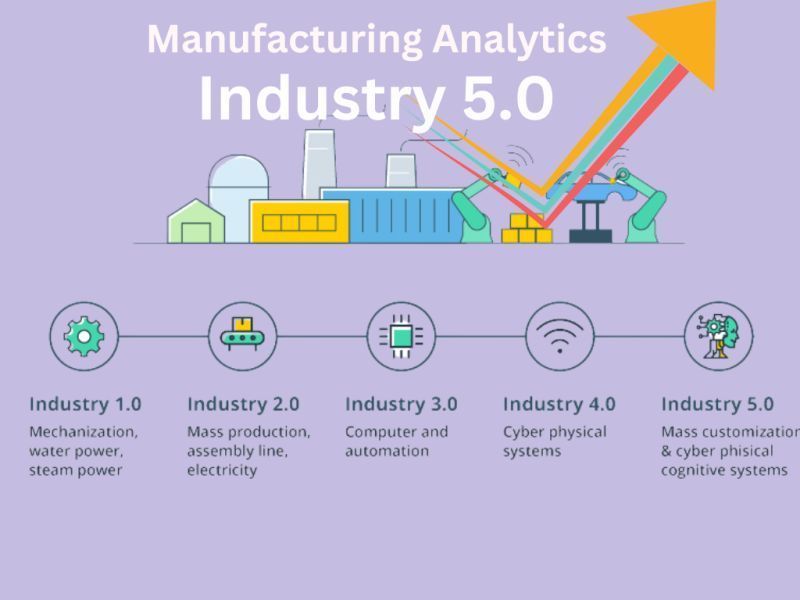

Industry 5.0 is a relatively new concept that refers to the integration of human intelligence with advanced technologies such as artificial intelligence, machine learning, and robotics. It represents a new stage in the evolution of industry and manufacturing, where human creativity and problem-solving abilities are combined with cutting-edge technologies to create innovative and efficient manufacturing processes.

In the context of Manufacturing Execution Systems (MES), Industry 5.0 refers to the use of advanced technologies to optimize and streamline manufacturing operations, while still leveraging the unique skills and insights of human operators. MES are software systems that track and manage the production process from raw materials to finished products. They provide real-time information on production status, inventory levels, and quality control, and can help identify bottlenecks and inefficiencies in the manufacturing process.

With the advent of Industry 5.0, MES can be enhanced with technologies such as machine learning, computer vision, and robotics to further optimize manufacturing operations. For example, machine learning algorithms can be used to analyze production data and identify patterns and trends, allowing manufacturers to anticipate and address potential issues before they occur. Computer vision technology can be used to automate quality control checks, reducing the need for manual inspection and improving product quality. Robotics can be used to automate repetitive or dangerous tasks, freeing up human operators to focus on more complex and creative aspects of the production process.

In short, Industry 5.0 in MES represents a new era of manufacturing, where advanced technologies and human intelligence work together to create more efficient and effective production processes.

The main functions of MES include:

- Production planning and scheduling: MES provides a platform for manufacturers to plan and schedule their production activities. This includes creating work orders, defining production schedules, and assigning resources to different tasks.

- Shop floor control: MES enables manufacturers to monitor and control their shop floor activities in real time. This includes tracking the progress of production jobs, managing machine downtime, and ensuring that operators are following standard operating procedures.

- Quality management: MES provides manufacturers with a platform to manage their quality control activities. This includes tracking defects, managing quality inspections, and ensuring that products meet customer specifications.

- Inventory management: MES enables manufacturers to manage their inventory levels in real time. This includes tracking raw materials, work-in-progress, and finished goods inventory levels.

- Performance analysis: MES provides manufacturers with the ability to analyze production data and identify areas for improvement. This includes analyzing machine utilization, cycle times, and overall equipment effectiveness (OEE).

Final Thought:

Manufacturing Execution System (MES) is a critical component of modern manufacturing operations. By providing manufacturers with real-time visibility into their production processes, MES enables them to make informed decisions that improve efficiency, quality, and overall performance. MES plays a vital role in helping manufacturers to optimize their production processes, reduce costs, and deliver products that meet customer requirements. With the increasing use of automation and digital technologies in manufacturing, the importance of MES is only set to grow in the coming years.