Digital Twins technologies are virtual replicas of physical assets that help streamline processes or systems that mirror real-time data and operational conditions. They provide solutions using Artificial Intelligence technology. In this article, we will discuss the influence of Digital Twins and AI In manufacturing in terms of how they are revolutionizing production and maintenance by optimizing operations, enabling predictive maintenance, and enhancing overall efficiency.

Why digital and AI solutions for the manufacturing industry

The manufacturing industry is already at a turning point, with most companies implementing Industry 4.0 and driven by the challenges of globalization, increasing competition, fluctuating market demands, and sustainability concerns.

So, manufacturers must remain competitive and efficient and embrace Digital Twin and Artificial Intelligence (AI) solutions.

Here’s why these technologies are essential:

- Real-Time Insights and Optimization

- Digital Twin and AI Integration: A digital twin integrating AI creates a virtual replica of physical systems, providing real-time visibility into operations. Manufacturing operation managers can simulate processes, identify inefficiencies, and optimize performance without disrupting production precisely. AI analyzes data from digital twins and provides actionable insights for fine-tuning operations, reducing downtime, improving product quality, and enhancing the performance of the manufacturing plant.

- Predictive Maintenance and Reduced Downtime

- Digital twins and AI-driven maintenance: This combo helps monitor machine health continuously, predicting failures before they occur and providing predictive measures. Ultimately, this minimizes unplanned downtime and effectively reduces maintenance costs. Alongside this, it helps scenario-based simulations and builds “what-if” analyses to prepare for potential disruptions and keep operations running smoothly.

- Process Optimization and Efficiency

- Workflow Enhancement: This combo allows manufacturers to virtually test and refine production processes and achieve higher efficiency and lower waste by collecting data and using AI Algorithms to optimize supply chains, production schedules, and resource allocation, ensuring smooth workflows and maximum output.

- Improved Quality Control

- Digital Twin Monitoring and AI in Defect Detection: Virtual models provide detailed insights into production lines, identifying deviations and ensuring consistent quality during the manufacturing process; the AI observes the data, analyses them and detects the quality issues or degradation from the collected data, the process helps to understand the quality issues and concern team can address the defects and recommendation system will give the appropriate guidance and supporting measures to correct the defects on time.

- Sustainability and Energy Efficiency

- Energy Optimization and Sustainable Practices: With the help of Digital twins, we could simulate along with AI-powered systems to analyse resource utilization, supporting waste reduction and safe energy usage across operations in the manufacturing plant and identifying areas to reduce consumption and costs effectively and build eco-friendly manufacturing

- Supply Chain Resilience and Agility

- Real-Time Visibility: Digital twins and AI Integration provide a comprehensive view of supply chains, enabling manufacturers to identify bottlenecks and improve logistics with AI prediction capabilities such as forecasting demand and anticipating supply chain disruptions, and helping manufacturers adapt quickly to market changes and back to the track in their supply chain management aspects and strength the process and improve the sustainability and market competition

- Workforce Empowerment and Safety

- Training Simulations: The greatness of the Digital Twins create realistic training environments for workers that help them upskill without risking live production, and AI systems monitor working conditions and proactively identify hazards, ensuring worker safety in terms of AI-enhanced safety

- Competitive Advantage in Industry 4.0

- Innovate Strategic Edge and Adaptability: Manufacturers can adopt digital twin and AI solutions to innovate faster, reduce costs, deliver superior customer experiences, and increase sustainability. These technologies also enable businesses to adapt to changing market demands and maintain a competitive edge.

Key Exercises for Implementing Digital Twin and AI in the Manufacturing Industry

Let’s understand the key exercises in the Manufacturing Industry to implement Digital Twin and AI.

Optimizing Production Lines

Digital twins and AI integration allow manufacturers to effectively simulate and analyze production processes in a virtual environment. Analyzing outcomes helps identify bottlenecks, test process changes, and optimise workflows without disrupting plant-level operations.

For instance, a factory digital twin and AI implementation can redesign production schedules, reducing overtime requirements and cost savings, which ultimately leads to improved productivity and reduced downtime.

Enabling Predictive Maintenance

By continuously monitoring equipment health through real-time data, this combo can predict when machinery will likely fail or if maintenance assistance is required. This proactive approach allows manufacturers to address issues well ahead of the timeline before they become costly problems, reducing unplanned downtime and extending equipment lifespan.

For example, digital twins and AI can monitor machinery’s condition and identify variances that indicate the need for preventative repairs or maintenance before a serious problem occurs. They facilitate predictive maintenance by continuously monitoring equipment health through sensor data and actionable insights and guidance. Thus, unexpected breakdowns and extended equipment lifespans are prevented.

Enhancing Efficiency

Digital twins and AI integration provide additional insights into energy consumption, machine performance, and process inefficiencies through real-time monitoring and data analysis. This information enables manufacturers to make informed decisions that enhance operational efficiency and reduce costs.

For example, digital twins can simulate various production scenarios and provide insights into energy consumption, machine performance, and process inefficiencies through real-time monitoring and data analysis. This information enables manufacturers to make informed decisions that enhance operational efficiency and reduce costs.

Let’s do some practical exercises

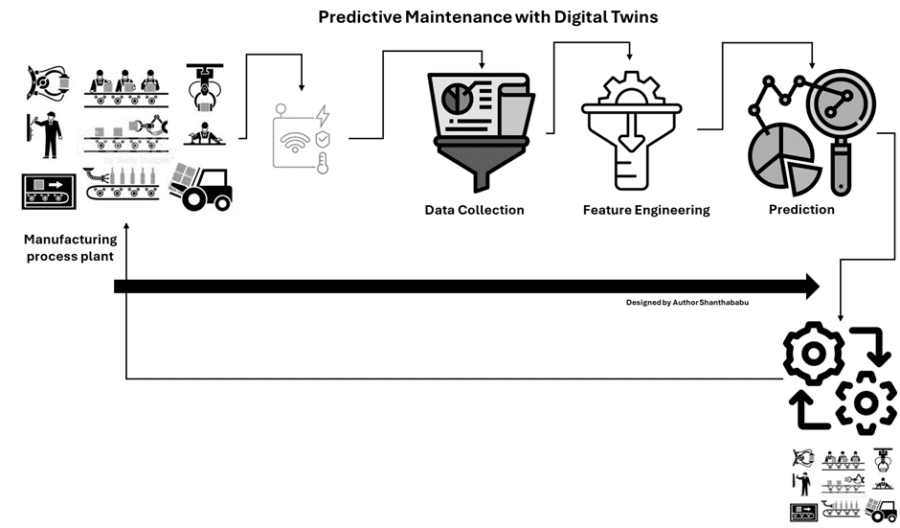

Sample Scenario: Predictive Maintenance with Digital Twins

Scenario: A manufacturing plant utilizes digital twins to monitor the health of its machinery. Sensors attached to machines collect data such as temperature, vibration, and operational hours. This data is fed into the digital twin, which uses machine learning algorithms to predict potential failures.

Implementation using Python

Data Collection: Gather sensor data from machinery

import pandas as pd

Sample data representing sensor readings

data = {

‘timestamp’: [‘2024-12-29 10:00’, ‘2024-12-29 11:00’, ‘2024-12-29 12:00’],

‘temperature’: [75, 78, 80], # in degrees Celsius

‘vibration’: [0.02, 0.03, 0.05], # in mm/s

‘operational_hours’: [1000, 1001, 1002]

}

df = pd.DataFrame(data)

Feature Engineering: Prepare the data for model training by creating relevant features

# Calculate rolling mean of temperature

df[‘temp_mean’] = df[‘temperature’].rolling(window=2).mean()

Model Training: Train a predictive model to forecast machinery failure.

From sklearn.model_selection import train_test_split

from sklearn.ensemble import RandomForestClassifier

#Sample target variable indicating failure (1) or no failure (0)

df[‘failure’] = [0, 0, 1]

#Features and target

X = df[[‘temperature’, ‘vibration’, ‘operational_hours’, ‘temp_mean’]].dropna()

y = df[‘failure’].dropna()

Split data

X_train, X_test, y_train, y_test = train_test_split(X, y, test_size=0.2, random_state=42)

#Train model

model = RandomForestClassifier()

model.fit(X_train, y_train)

Prediction: Use the trained model to predict potential failures

#Predict on new data

predictions = model.predict(X_test)

Integration with Digital Twin: Incorporate the predictive model into the Digital Twin framework for real-time monitoring and maintenance scheduling.

def predict_failure(sensor_data):

Preprocess sensor_data as done during training

…

return model.predict(sensor_data)

usage

new_sensor_data = pd.DataFrame({

‘temperature’: [82],

‘vibration’: [0.06],

‘operational_hours’: [1003],

‘temp_mean’: [81]

})

failure_prediction = predict_failure(new_sensor_data)

Digital twins offer significant benefits in manufacturing, but their implementation comes with specific challenges. Here’s an overview

Benefits:

- Predictive Maintenance: By continuously monitoring equipment health through real-time data, digital twins can predict when machinery is likely to fail or require maintenance, allowing manufacturers to address issues before they become costly problems.

- Process Optimization: Digital twins can simulate production lines, identify bottlenecks, and analyze alternative configurations, allowing manufacturers to optimize workflows without disrupting operations.

- Enhanced Product Development: Digital twins transform product development by enabling designers and engineers to design, test, and perfect products within a virtual space before constructing physical prototypes.

- Improved Quality and Safety: Manufacturers can ensure product quality and safety by identifying and rectifying issues in the virtual environment before they manifest in the physical world.

Supply Chain Management: Digital twins offer significant improvements in supply chain management by providing a comprehensive digital replica of the entire supply chain network. This allows companies to model, analyze, and optimize operations in the whole supply chain.

Challenges:

- High Initial Costs: Implementing digital twins requires significant upfront investment in infrastructure and technology integration.

- Data Integration and Management: Digital twins generate large sets of data from multiple sources, and differing data formats can complicate integration and interoperability.

- Scalability Issues: Without effective scalability, the benefits of digital twins might not translate well across more extensive or diverse business segments, limiting their utility to only certain areas or departments.

- Security Concerns: Integrating digital twins with machine learning, artificial intelligence, and sensitive instruments raises significant privacy, security, and ethical concerns.

- Complexity in Data Management and Analysis: The success of digital twin technology depends crucially on accurate and timely data collection and analysis, which can be complex and resource-intensive.

Understanding these benefits and challenges is crucial for manufacturers considering the adoption of digital twin technology to enhance their operations

Conclusion

Digital twins are transforming the manufacturing landscape by providing a virtual environment to optimize production processes, predict maintenance needs, and enhance overall efficiency. As technology advances, integrating digital twins into manufacturing operations is set to become increasingly sophisticated, offering even more excellent opportunities for innovation and improvement.