A recent article in BusinessWeek titled “Farmers Fight John Deere Over Who Gets to Fix an $800,000 Tractor” highlights a key challenge with which organizations must wrestle on their Digital Transformation journey: how to create win-win scenarios for one’s customers.

The article asks, “Who really owns a John Deere? Is it the farmer who pays $800,000 for it, or the company that won’t let the farmer fix it on their own?”

As a good old Iowa boy (Charles City, IA), I can understand why farmers that John Deere forbids them from servicing their own tractors; that only authorized dealer can perform maintenance on these machines. As the article says:

‘’Anything a farmer does on a modern tractor, beginning with opening the cab door, generates messages captured by its main onboard computer, which uploads the signals to the cloud via a cellular transmitter located, in many Deere models, beneath the driver’s seat. These machines have been meticulously programmed and tested to minimize hazards and maximize productivity, Deere says, and it’s all too complicated for farmers to be getting involved in.”

Forcing farmers to have all tractor repairs done by a certified John Deere technician is not only more expensive, it delays getting necessary repairs done in a timely manner. “Meantime-to-Repair” is a critical key performance indicator when dealing with crops as unplanned delays in planting and harvesting can quickly turn into lost revenue and shrinking margins.

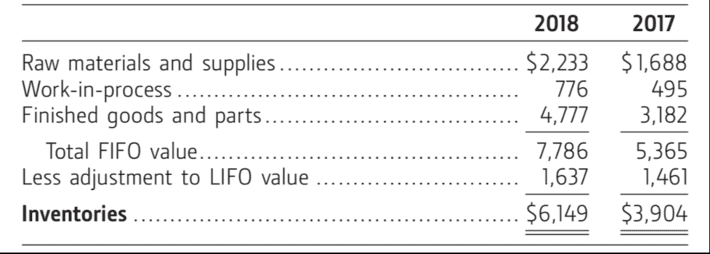

At stake here is more than just control of the operations of the tractor for John Deere. John Deere is taking this drastic action in part to protect its maintenance and parts business. From the John Deere 2018 Annual Report, we can see that the parts business was a substantial part of John Deere’s $37.4B in revenue (see Figure 1).

As the article states:

“Historically, the healthy profit margins of the parts and services units have helped smooth out earnings when demand for machines is down. For Deere and its dealerships, parts and services are three to six times more profitable than sales of original equipment, according to company filings. Farmers need to keep aging equipment running; that helped increase annual parts sales by 22%, to $6.7 billion, from 2013 to 2019, while Deere’s total agricultural-equipment sales plunged 19%, to $23.7 billion.[1]”

What are organizations to do to ensure a successful digital transformation? And what role do customers play in that digital transformation (hint: the most important role)?

Digitalization versus Digital Transformation

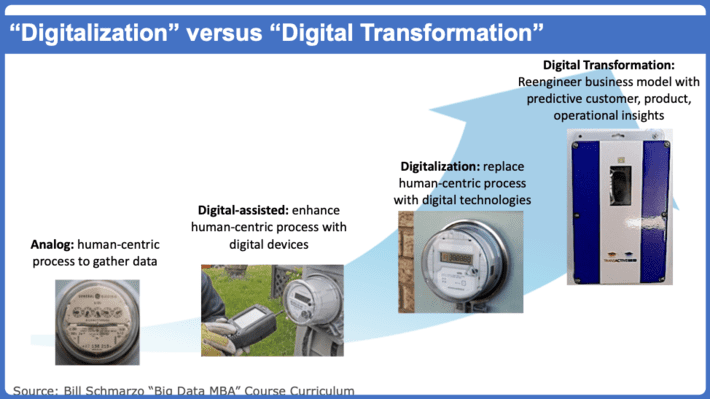

As I discussed in “Digtial Transformation is Messy, Dirty, and Ugly. Here’s How to Embrace it!”, there is a big difference between Digitalization and Digital Transformation. Digitalization enhances or replaces human-centric process with digital technologies, such as transmitting meter readings to the cloud using sensors on a more granular basis versus having human meter readers travel to the meter to get the reading every couple of weeks (see Figure 2).

Unfortunately, Digitalization of existing business processes and products still puts most of the operational and business risk on the customer. Digital Transformation, on the other hand, leverages the economics of data and analytics to re-engineer the the organization’s business models to create new sources of mutual customer value based upon customer, product and operational insights.

And that gets to the heart of my issue with the John Deere situation – all the benefits accrue to John Deere at the expense of their customers. John Deere gets all the product usage data which they use to engineer more profitable tractors and create farmer lock-in while protecting their parts business (through onerous contractual terms). And the farmer gets less agility and flexibility in their ability to fix their own problems in order to reduce unplanned operational downtime which has direct financial impact on their business.

I’d call that a win-lose scenario for the farmers.

However, there is a better business model that benefits both John Deere and the farmers that leverages all the data and analytic investments that John Deere is making in their products while doing a better job of spreading the value and risk between the manufacturer (John Deere) and their customers (farmers). That’s the “Product-as-a-service” or Xaas business model.

Let me explain.

Digital Transformation Leverages Xaas to Create Win-Win Customer Scenarios

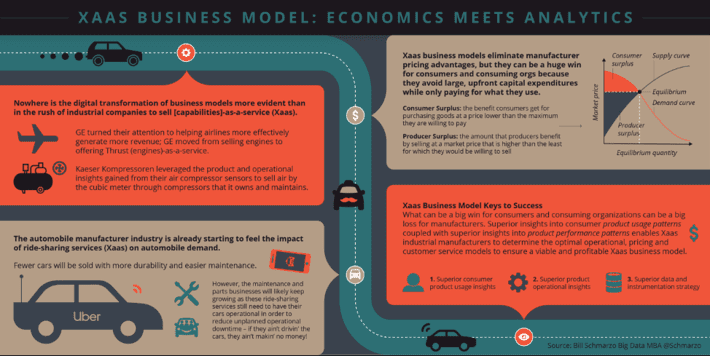

Digital Transformation builds business models that enable win-win customer scenarios: a win for the customer, and a win for the manufacturer. And that’s leading organizations to transition towards a “Capability-as-a-service” business model (called Xaas) in which customers only pay for what services (or time) that they actually use the product. We are already seeing industrial companies move in this direction including:

- General Electric (GE) is transitioning away from selling traditional industrial products towards selling ‘as-a-service’ packages by wrapping data and digital solutions around its core offering.

- Kaeser Kompressoren, who manufacturers large air compressors, leverages product usage, performance and condition data from its air compressors to sell air by the cubic meter… Air-as-a-service.

To ensure a viable and profitable Xaas business model, organizations must master the world of data and analytics to uncover superior insights into consumer usage and product performance patterns to determine optimal consumption pricing and customer Service Level Agreements (SLAs).

Yea baby, superior insights required!

Note: See “Xaas Business Model: Economics Meets Analytics” for more insights into the data and analytic requirements for a successful Xaas business model.

The win-win for the customer is that the manufacturer now shares in the customers’ operational risks. If it’s planting or harvesting season, then farmers are probably going to want a Service Level Agreement that guarantees 99.5% operational uptime (which is about 50 minutes per week). And the farmer would pay a higher premium to have that level of service during their most important and riskiest times of their operations.

Even More: Digital Transformation to Win-Win-Win

But wait, there’s more to this story.

If you really want to increase the success of your Digital Transformation journey, then start thinking win-win-win. That is, what is the win for the manufacturer, what is the win for your customer, and what is the win for your customer’s customers. If your customer is a theme park operator, then what are the wins that your Xaas consumption model can provide to your Theme Park guests? If your customer is an Agricultural Solutions provider, then what are the wins that your Xaas consumption model can provide your Agricultural Solutions farming customers?

In John Deere’s case, John Deere could adopt a Xaas win-win-win business model that’s a win for them (in providing new products and services to their customers) for their customer (dealerships) in providing new sources of revenue and a win for the dealer’s customers (the farmers) in providing uptime guarantees during the farmers’ risky times of the season. This win-win-win Digital Transformation business model is built upon mutual value and risk sharing for all participants.

There are some design thinking techniques that I have just started to play with – such as Strategic Doing – that drive this win-win-win thinking. And when you are focused on leveraging customer, product and operational insights to re-engineer your business model to drive mutual value for your customers and your customer’s customers, then you are onto something very epic!

[1] “Farmers Fight John Deere Over Who Gets to Fix an $800,000 Tractor”