Manufacturing companies have traditionally been slow to react to the advent of digital technologies like intelligent robots, drones, sensor technology,artificial intelligence, nanotechnology & 3d Printing.

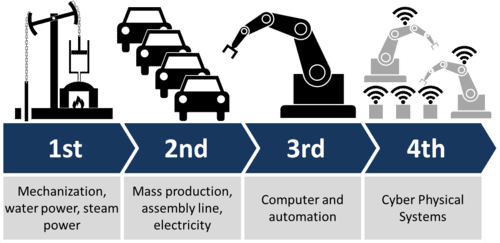

Industry 4.0 has changed manufacturing. At a high-level, Industry 4.0 represents the vision of the interconnected factory where all equipment is online, and in some way, is also intelligent and capable of making its own decisions.

The explosion in connected devices and platforms, abundance of data from field devices and rapidly changing technology landscape has made it imperative for companies to quickly adapt their products and services and move from physical world to a digital world.

Today, Manufacturing is transforming from mass production to the one characterized by mass customization. Not only must the right products be delivered to the right person for the right price, the process of how products are designed and delivered must now be at a level of sophistication.

First step in digitization is to analyze current state of all systems starting R&D, procurement, production, warehousing, logistics, marketing, sales & service. The digitization of manufacturing impacts every aspect of operations and the supply chain. It starts with equipment design, and continues through product design, production process improvement and, ultimately, monitoring and improving the end-user experience.

- Digital transformation revolutionizes the way manufacturers share and manage product & engineering design, specs on the cloud by collaborating across geographies.

- Down time and reliability are critical when it comes to the operation of equipment and machines on a shop floor. With Big data Analytics, the quick and easy access to this operation data, production information, inventory, quality data gives ability to quickly adjust to machine status across the enterprise.

- Quality and yield is directly related to manufacturing processes as to how raw materials are used, inspected, manufactured, and how everything comes together. This really determines the quality level of the products. Cognitive computing enables earlier identification of nascent quality problems, increased production yield, and reduction of problems that lead to service and warranty costs.

- Implementing smarter resource and supply chain optimization strategies helps to improve the cost efficiency of these resources like energy consumption, worker safety, and employee resource efficiency.

- Service Excellence is also an important part of the strategy that companies are using to achieve digital transformation in the manufacturing space.

Connected Devices (IoT) are changing the paradigm of delivering after-sales service. Some of the advantage are most prevalent in several selected industries, such as industrial equipment, power generation and HVAC providers:

- Push Service Notifications

- How is your asset health?

- How is your asset usage?

- Predictive/ Preventive Maintenance

- Break-Down Assistance

- Usage-based Billing

- Spares Fulfillment

General Electric’s jet engines combine cloud-based services, analytics and on-line sensors to report usage and status and help predict potential failures. The result is improved uptime and lower cost of ownership. Additive manufacturing (3D printers) for prototyping help shorten the iteration cycles in the design process and help to turn innovation into value. 3D printing is also quickly gaining ground in the commercial manufacturing of customized products in low volumes.

Smart machines integrated with forklifts, storage shelves and production equipment.

The machines are able to take autonomous decisions and communicate with each other to drive material replenishment, trigger manufacturing and much more. Industry 4.0, allowing manufacturers to have more flexible manufacturing processes that can better react to customer demands.